8. Oblique Duct

Exercise 8: Oblique Duct

Version compatibility

This exercise was carried out with version 27.0 (Vertex 2021).

Table of Contents

In this exercise you will learn to

- How to use a jig to model sheet metal parts.

- How to copy a face from another part.

- How to create a sheet metal part from a surface chain.

- How parts are positioned using coincidence constraints.

Functions to be used:

- New > Part

- Faces > Copy Face > To volume.

Add Flange.

- Operation:

- In the assembly: Clipboard> Copy / Paste.

- In the assembly: Coincidence constraint between surfaces and Coincidence constraint between lines.

Main stages

- Create a new part in the assembly.

- Copy the surface chain of the Jigi part into a volume model.

- Add flanges.

- Copy parts.

- Use constraints to locate the parts.

Starting point

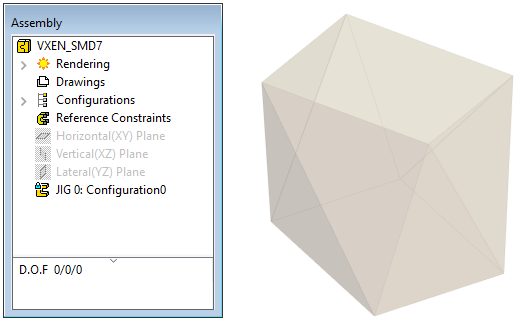

In the past, an assembly has been created in which the jig has been modeled.

- Continue doing this exercise in the previous exercise model.

- If you have not yet modeled a jig, see the instructions from the previous exercise.

- You can also download a model from the end of the previous exercise.

Create a new part in the assembly

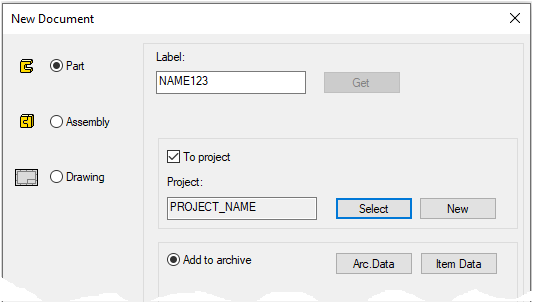

- Right-click function: New > Part.

- Enter the label (which is also the name of the model and by default will be the name of the drawing).

- Enter the archive information by clicking Arc.Data.

- Accept (or create a new) project, where the model will be saved.

- OK.

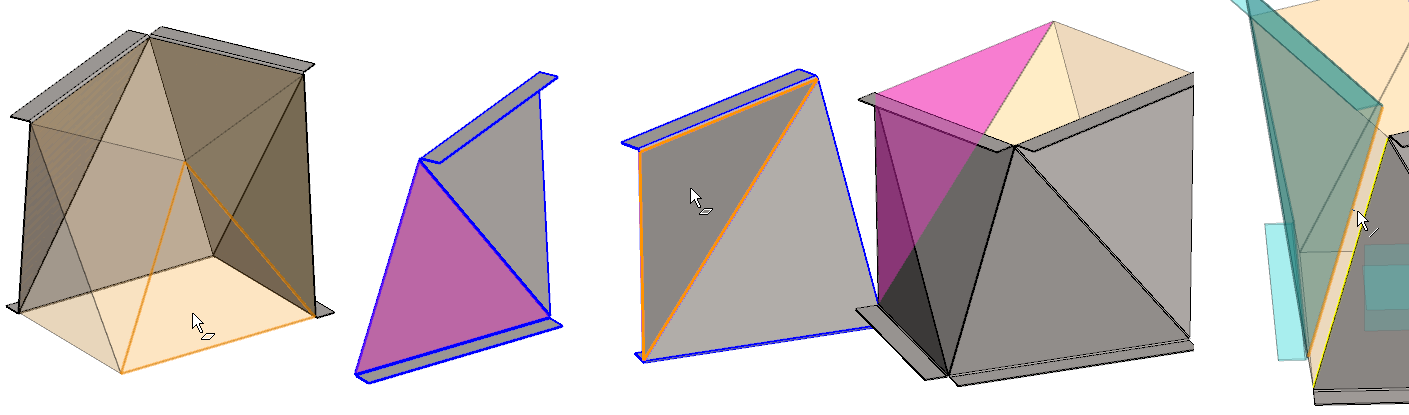

Copy the surface of the jig into a sheet metal part.

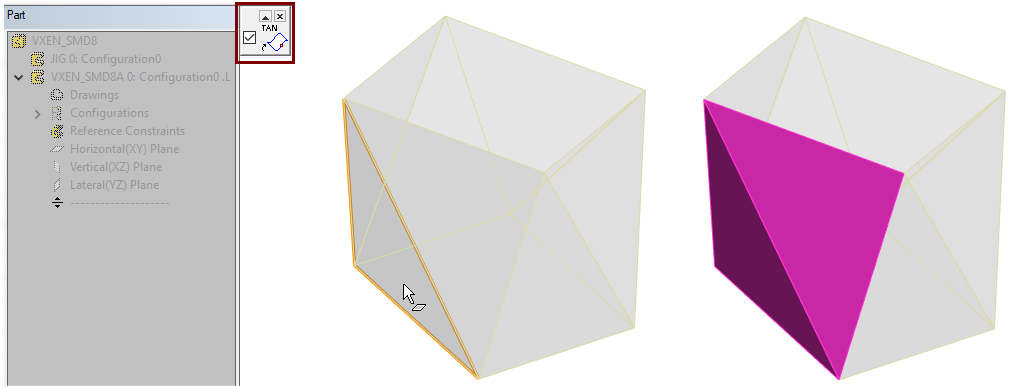

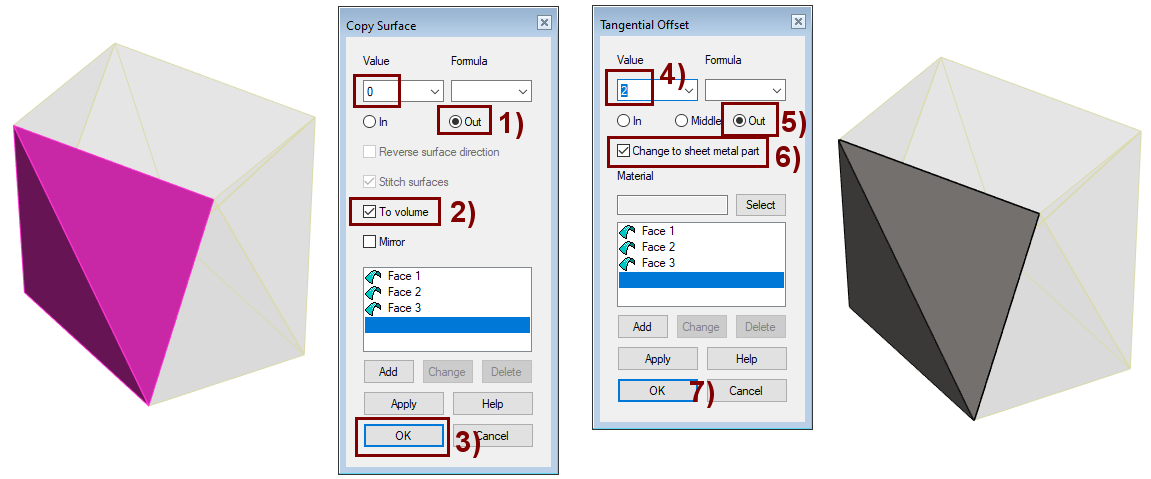

- Right-click function: Faces > Copy Face.

- Select TAN in the upper left corner of the desktop, ie the selection of the tangential surface chain.

- Click a face.

- The program searches for tangential surfaces.

- Dialog Copy Surface opens.

- Leave the value: 0 (the surface is copied exactly to the location of the old surface), shown in the figure.

- Click: Out, shown in the figure 1).

- Select: To Volume, shown in the figure 2).

- OK, shown in the figure 3).

- Dialog Tangential Offset opens.

- Enter the sheet metal thickness value: 2, shown in the figure 4).

- Click: Out, shown in the figure 5).

- The sheet metal comes out of the surface.

- The sheet metal comes out of the surface.

- Select: Change to sheet metal part, shown in the figure 6).

- This changes the properties of the part to sheet metal.

- This changes the properties of the part to sheet metal.

- OK, shown in the figure 7).

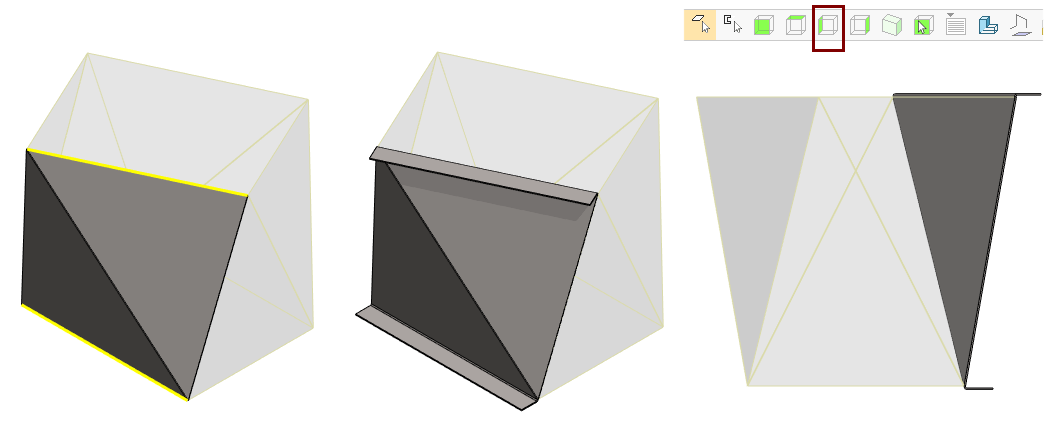

Add flanges (mounting edges) to the part

- Click to the two lines on the outside edge of the sheet metal.

- Right-click function: Add Flange.

- Enter the value:

- Radius: 2

- Angle: 90 or 100 (The value 100 found by experiment).

- Length: 40

The program suggests an angle of 90. You can accept it to see if the part looks valid.

- Turn the projection in the direction: Left View.

- If necessary, edit the Flange feature (for example, by double-clicking it on the feature tree) and try other values.

Return from part to the assembly:

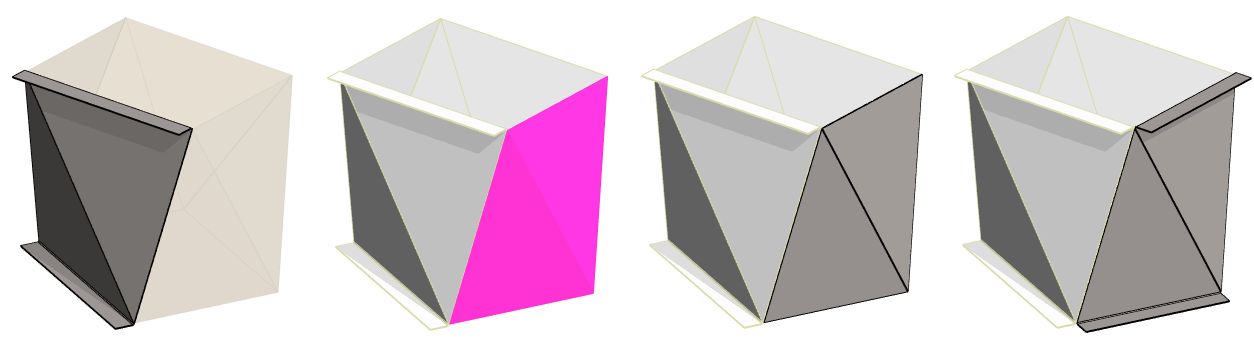

Create another sheet metal part in the same way

- Right-click function: New > Part.

- Right-click function: Faces > Copy Face.

- Right-click function: Add Flange.

- In this part, the angle 96.4° angle looked good.

Return from part to the assembly:

Complete the assembly by copying the parts

- Click a part.

- Right-click function: Clipboard > Copy.

- Right-click function: Clipboard > Paste.

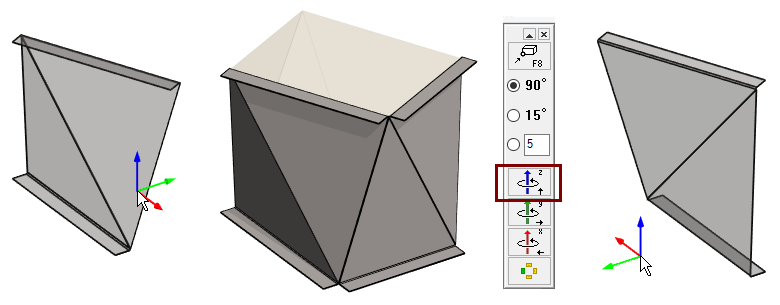

- Before positioning, turn the part 90 ° twice around the blue axis.

Use the Conincident constraint to locate the parts

Add three Conincident constraint between each part and the jig.

- Two pairs of faces.

- One pair of lines.

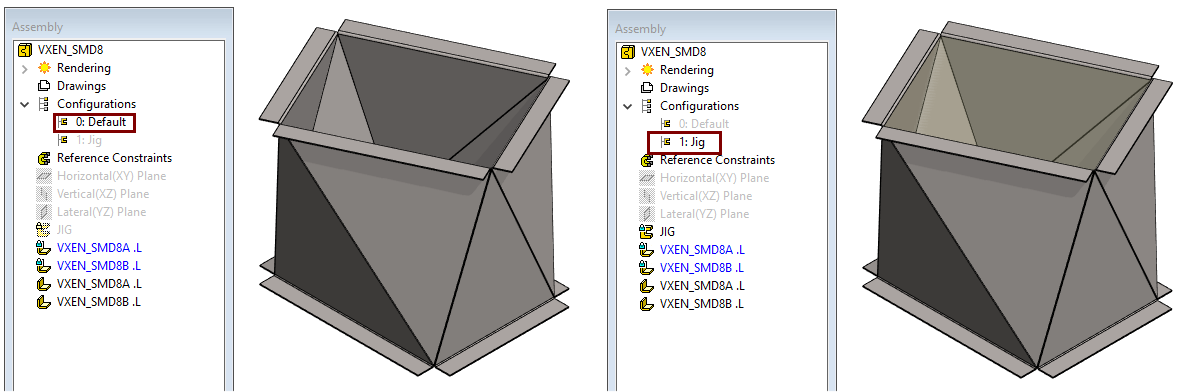

Hide the jig

You should create a new configuration in the assembly where the JIGI part is visible and hide it in the O: Defauld configuration.

- Click Configurations. (From the feature tree)

- Right-click function: Add Configurations.

- Select this new configuration: 1: Configuration 1.

- Right-click function: Properties.

- Enter a new name: Eg Jig.

- OK.

- Activate the configuration: 0: Default (Either double-click or Right-click function).

- Click the JIG part.

- Right-click function: Hiding > Hide.

- Click the configuration: 1: Jig.

- Right-click function: Update Hiding State.

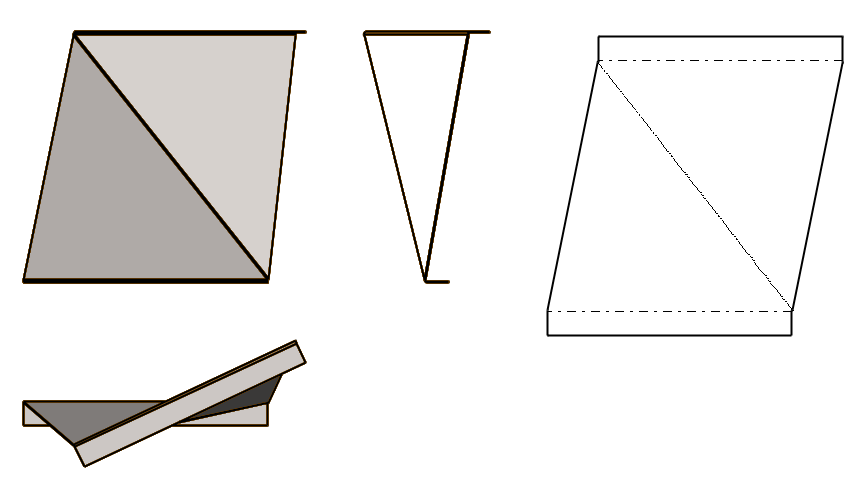

Create drawings for parts

- Take each part in turn for editing.

- Enter or select a raw material for the parts (See exercise 2: Box)

- Create a drawing.

- Click the Drawings in the feature tree.

- Right-click function: New Drawing.

- Select scale (1: 5 to fit geometry on A3 form).

- Select projections: Front, top, left and Flatten sheet.

Save the dawing

- File > Save or click

- Remove the drawing from the desktop.

- Return from part to the assembly

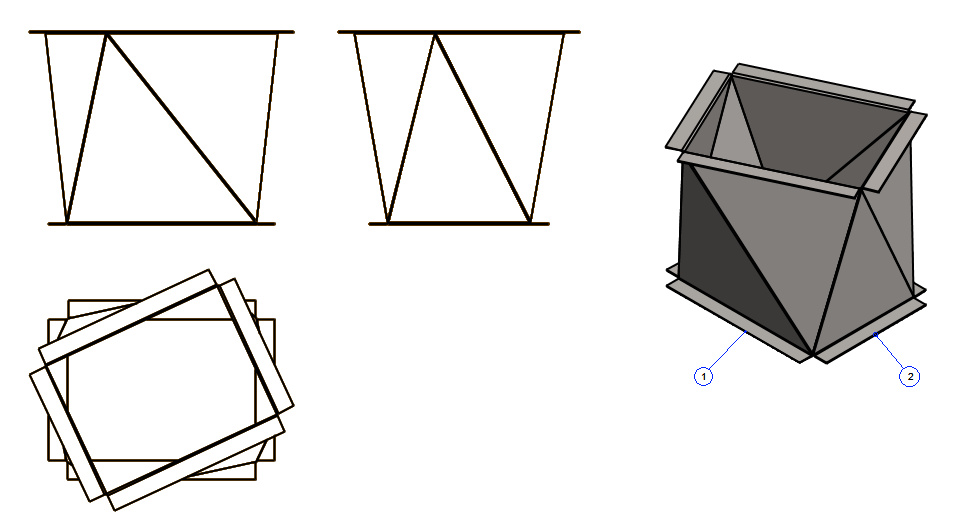

Create a drawing for the assembly model

- Click the Drawings in the feature tree.

- Right-click function: New Drawing.

- Select projections, such as front, top, left, and ISO, -45 front right.

- Select scale (1:5 to fit geometry on A3 sheet).

- Add part numbers: Drawing> Machanical > Parts list> Part number.

- Number > Number

- Exit the dialog.

- OK.

- Click the part (1 and 2) and the location of the part number ball.

Save the dawing

- File > Save or click

- Remove the drawing from the desktop.

Save the model

- File > Save or click

Download the assembly model (VX_SMD9.vxz) here.

- Includes Jig and both different sheet metal parts VX_SMD10 and VX_SMD11.