Assembly Structure vs. Item Structure

General

When building an assembly, the parts added usually also appear in the item structure, meaning that the geometric structure of the assembly and the item structure in Flow are the same. However, there can be exceptions.

Parts in the assembly that are not in the structure:

For example, parts that are needed for assembly attachment to neighboring assemblies might be shown in the assembly.

Or there might be props in the assembly (e.g., a human model) to illustrate the scale.

The assembly contains fewer parts than the product structure:

For instance, not every fastening screw is modeled; some may only be included in the product structure.

The product structure contains parts that are not in the assembly:

For example, lubrication oils, sealing glues, or packaging materials.

Working with Vertex G4 in connection with Flow: Vertex G4

Compare Structures

This function compares the assembly structure and the item structure.

(1) Select the Product Structure tab.

By default, it is located under the Assembly Tree.

You can also detach the Product Structure tab into its own floating window or drag and drop it to the right edge of the workspace.

(2) Click on the head item of the structure.

(3) Select the context-sensitive function Compare.

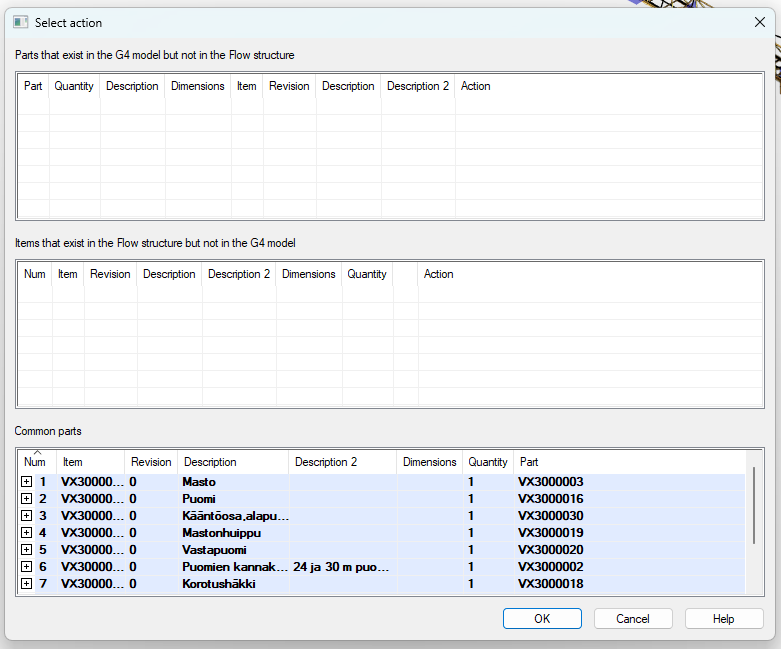

Vertex G4 opens a three-part dialog window titled "Select Action."

Table Section | Shows... | Functionalities |

|---|---|---|

Top Section | Parts that are in the assembly but not as items. | Remove part. Link to item (selected from the middle section). |

Middle Section | Parts that are items in the product structure but not in the model. | Add geometry of one or all parts to the model. Remove item from the product structure. |

Middle Section | Parts that are present in both the model and the product structure. | No actions available. |

Edit Model

(1) Click on the row in the comparison table.

(2) Open the context menu and select an action (see actions in the table above).

(3) Confirm the actions by selecting OK.

Significance of Structural Differences

The model and its corresponding drawing represent the product with sufficient accuracy for manufacturing.

In this case, not all small parts (e.g., screws, nuts, and washers) need to be included in the model if their positions can be identified through annotations in the drawing.

However, all parts in the product structure should be included in Flow's product structure (i.e., the item structure) to ensure that manufacturing and purchasing have the necessary information about required raw materials and components.

Typically, the bill of materials associated with the drawing comes from Flow, not the model, so the structure must be accurate in Flow, but not necessarily in the model.

In some cases, the bill of materials is desired to be compiled from the model, even when Vertex G4 is connected to Flow. In this scenario, models and drawings exist in Flow, but the models do not have any item numbers associated with raw materials or components.

The keyword

partslist_in_cadwith a value of 1 is used to manage the collection of the bill of materials from the model.For more details, refer to the guide on Calculate Weight in Vertex G4 Model, specifically the section on Vertex G4 Plant (Plant Design).