Best Practices for Setting Up Light Gauge Steel Customizations

As a Vertex administrator you may need to customize the light gauge steel connections for optimal use of the machine. For example, you may need to change the lip cut, web notch and swage sizes in the 3d frame model so that they match the same size of the tools on the machine, You could also change the hole sizes and shapes to improve the visualization and detailing.

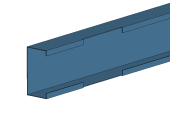

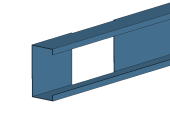

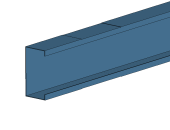

Lip Cut |  Web Notch |  Swage |  Service hole |

|---|

One fixed size for the lip cut, web notch and swage

If you are using only one profile flange (width of the profile) size then you only need to set the required tool sizes once. With no customization by default the lip cut, web notch and swage have the smallest possible size by settings the sizes to 0.

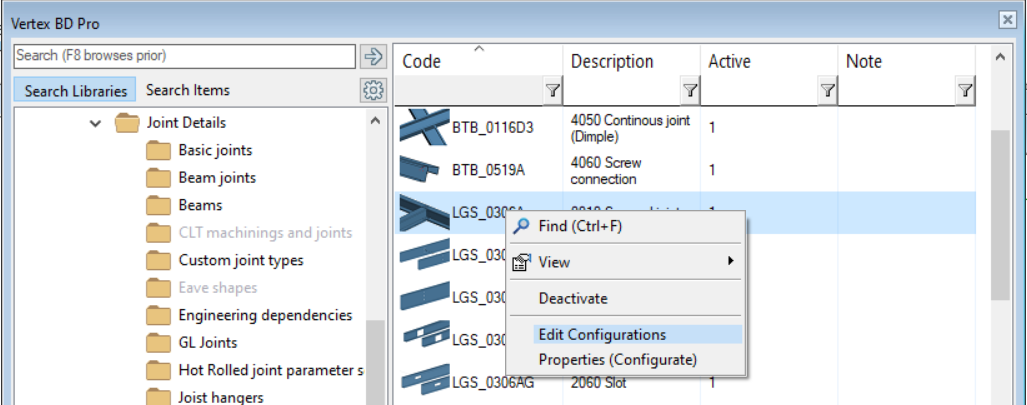

Select System | Libraries |

Open the folder System Libraries / Other / Joint Details / Light Gauge Steel joint types.

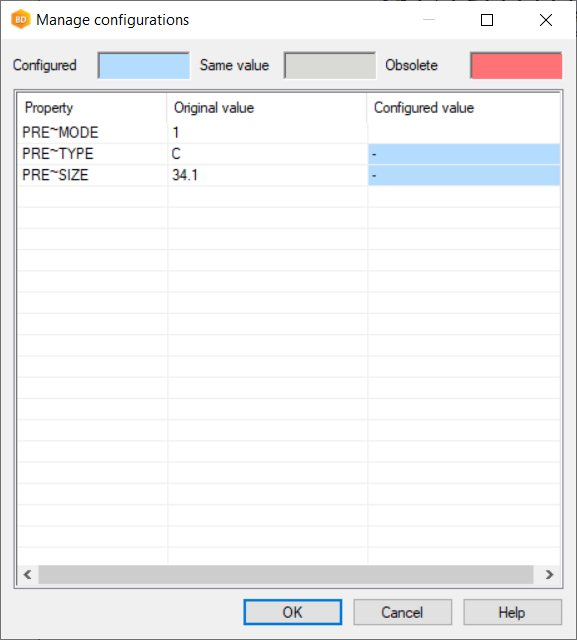

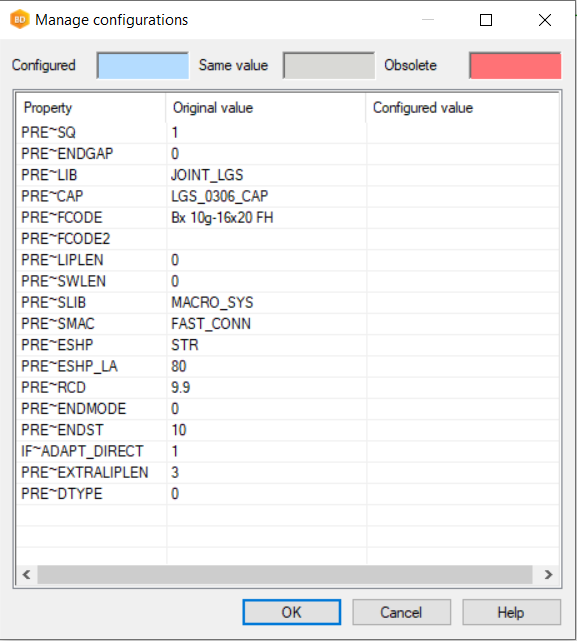

Right-click on a joint you wish to configure and choose Edit Configurations.

The parameters to change are:

PRE~LIPLEN - Lip cut length and web notch length.

PRE~SWLEN - Swage Length.

For example PRE~LIPLEN=50 sets the lip cut and web notches to 50mm in length. You are free to change this value here and you can immediately regenerate panel parts to see the effect.

Note - The system library is marked as Configured when you edit the parameters.

Separate sizes for the lip cut, web notch and swage

Some roll forming machines have different sizes for the lip cut, web notch and swage tools based on the profile flange. In this case, the parameters.xml file is not enough. It's best practice to set these sizes into the profile library itself.

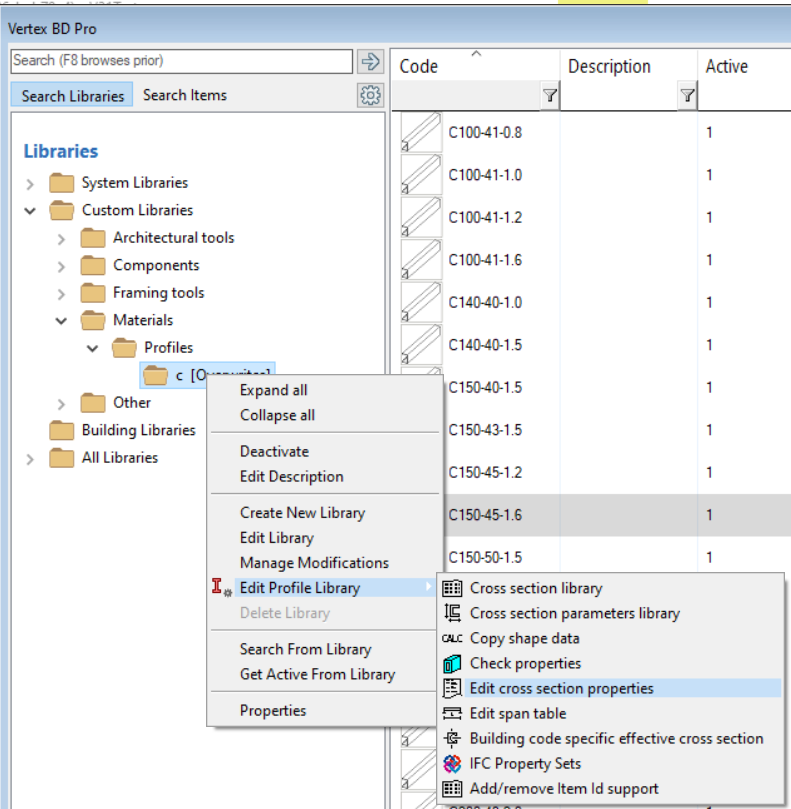

Select System | Libraries |

Open the folder Custom Libraries / Materials / Profiles.

Choose the library to update.

Right-click and select Edit Profile Library > Edit cross section properties. The text file "profprop" will open, choose your text file editor, for example Notepad.

You can add material groups at the end of the file

mat_group= 1

mat_param= S.NC.LIPCUTLEN 46

mat_param= S.NC.NOTCHLEN 48

mat_param= S.NC.SWAGELEN 55

mat_group= 2

mat_param= S.NC.LIPCUTLEN 70

mat_param= S.NC.NOTCHLEN 70

mat_param= S.NC.SWAGELEN 85

You can have as many material groups as you like, for example 3, 4 etc. Close and save the file. The browser becomes active again.

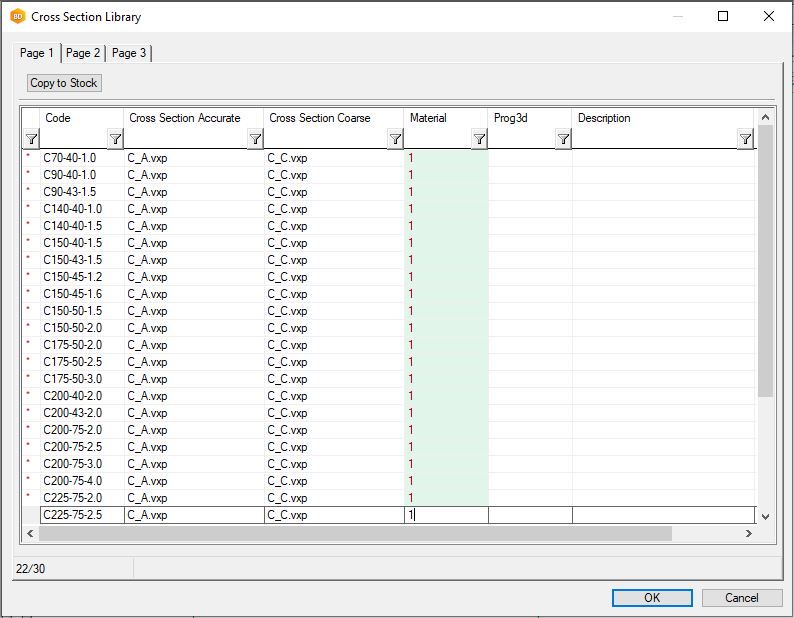

In the browser, right-click on the library you are editing again and select Edit Profile Library > Cross section library.

In the material group column, add the material group you wish the section code to use.

If you wish to use these new settings in an existing project you must update the drawn profiles first by going into the 3d frame and doing Modeling | Tools > Update Profiles from Library. Left-click on a profile and then CTRL-A to select all profiles. Then right-click and select OK to start the update process.

Keywords you can use

There are a couple of extra keywords you can use in the profprop file (Numerical values are given as examples):

mat_param= S.NC.LIPCUTLEN 46

mat_param= S.NC.LIPCUTDEPTH 3

mat_param= S.NC.NOTCHLEN 48

mat_param= S.NC.SWAGELEN 55

mat_param= S.DIMPLESLOT.ON 1 Turn the dimple slot on by default

mat_param= S.DIMPLEGAP 80 If the profile has a wider flange then the dimple to dimple distance will need to be increased for truss lintels and diagonal bracing.

mat_param= S.NC.DIMPLE_OFFSET 26 Some machines allow the dimple to be placed at a distance from the web (back) of the profile eg Scottsdale. By default the dimple is placed on the centre line.

mat_param= S.NC.SRV_HOLE_SHP C/RT/OB Shape of service hole C = Circular, RT = Rectangular, OB = Obround / Rounded rectangle

mat_param= S.NC.SRV_HOLE_SIZE 34/34x50 Size of service hole

mat_param= S.NC.LSRV_HOLE_SHP C/RT/OB Shape of large (Deep Joist) service hole C = Circular, RT = Rectangular, OB = Obround / Rounded rectangle

mat_param= S.NC.LSRV_HLE_SIZE 100/100x120 Size of large service hole

mat_param= S.NC.WEB_HOLE_SHP C/RT/OB/CGX Shape of web hole C = Circular, RT = Rectangular, OB = Obround / Rounded rectangle / CGX = Circular Hole group / MODSUB = Subtraction model

mat_param= S.NC.WEB_HOLE_MODEL FILE.vxm Subtraction model

mat_param= S.NC.WEB_HOLE_SIZE 10/13 Size of web hole

mat_param= S.NC.WEB_HOLE_QTY 3 Number of holes in this hole group

mat_param= S.NC.WEB_HOLE_SPAC 25 Triple web hole, hole spacing

mat_param= S.NC.WEB_HOLE_MODE 0 Bolt hole, mode = 0 means holes spaced from centre, 1 means from flange edge

mat_param= S.NC.ANC_HOLE_SHP C/RT/OB Shape of anchor hole C = Circular, RT = Rectangular, OB = Obround / Rounded rectangle. If not defined defaults to web hole shape

mat_param= S.NC.ANC_HOLE_SIZE 10/13 Size of ancor hole. If not defined defaults to web hole size

mat_param= S.NC.3WHOLE_QTY 3 Number of holes in this hole group

mat_param= S.NC.3WHOLE_SHP 25 C/RT/OB/CGX Shape of hole C = Circular, RT = Rectangular, OB = Obround / Rounded rectangle / CGX = Circular Hole group / MODSUB = Subtraction model

mat_param= S.NC.3WHOLE_MODEL FILE.vxm Subtraction model

mat_param= S.NC.3WHOLE_DIA 3 Triple web hole, hole diameter

mat_param= S.NC.3WHOLE_SPAC 25 Triple web hole, hole spacing

mat_param= S.NC.3WHOLE_MODE 0 Triple web hole, mode = 0 means holes spaced from centre, 1 means from flange edge

mat_param= S.NC.WEB_DIMPLE_QTY 2 Web Dimple quantity

mat_param= S.NC.WEB_DIMPLE_SPAC 60 Web Dimple spacing

mat_param= S.NC.ESHP RND Is piece end chamfered for diagonals STR=Straight, RND= Chamfered

mat_param= NC.EXTRALIPCUTLEN 5 Extra tolerance to the lip cut on diagonal swages pieces

For service holes, large service holes, web holes, triple holes from the "Area Tools" tree and "Tools" tree in the connection details browser you also need to set their size to "-" (minus character) under Edit Configurations to force read from the profprop file