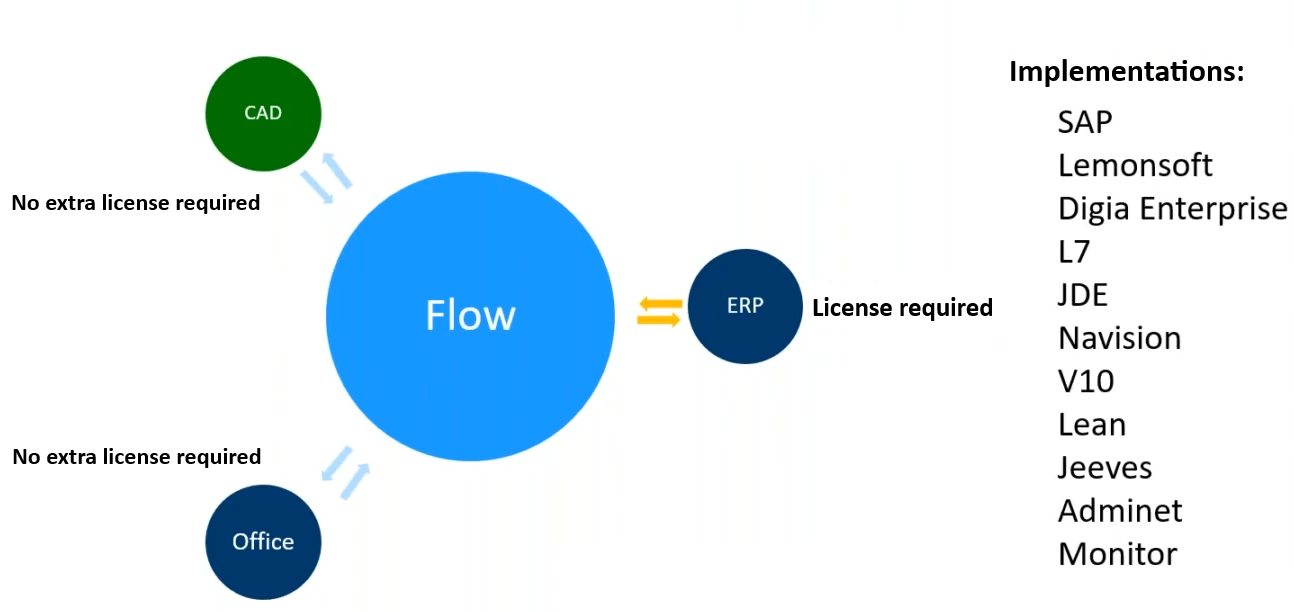

Flow and ERP interface

General

The ERP interface connects the processes of the design and Enterprise Resource Planning (ERP) systems.

Through the interface, the data produced by design, such as items and item structures, is transferred automatically from Flow to the ERP system.

The interface saves time and reduces errors caused by redundant data entry.

Interfaces can also be used to transfer item data for purchased materials and components from the ERP system to Flow.

- This is possible if the items managed in different systems can be clearly distinguished from one another.

- Primarily due to purchasing requirements, some companies have left the maintenance of purchase items in the ERP system, even though the maintenance of these could very well be handled in Flow.The interface also allows the transfer of project, customer, and supplier data, as well as the connections between them.

Division of Responsibilities between Flow and ERP

Vertex Flow

The role of Flow is to produce and maintain design data and to input, among other things, items and structures into the ERP system.

Design is responsible for creating, modifying, and revising the product structure related to the product.

All changes made to product structures are recorded in Flow.

Documents related to items and structures are managed in Flow/Sync.

ERP

The role of the ERP system is to support the control of manufacturing, operations, and order processing.

In the ERP system, the structure is supplemented with necessary work steps, the size of the production batches, and production planning.

- In some companies, work steps and resources are also input in Flow, from which data is transferred to the ERP system along with the item structure.As manufacturing progresses in the ERP system, the structure can be supplemented if necessary, for example, with information identifying components.

- Identification data may be required for product traceability purposes.In the ERP system, additional information can be added to items that design does not need, such as:

- Storage location and shelf

- Prices of purchased batches

- Suppliers of purchased batches

- Tax information

The primary storage location of the data determines the transfer direction.

The primary storage location is defined together with the customer when planning the integration of Flow and ERP.

Objekti | Flow | suunta | ERP |

|---|---|---|---|

Items | X | → tai ↔ | X |

Item structures | X | → | |

Manufacturing data | (X) | → | X |

Product data | X | ||

Supplier | X | → or ← | X |

Drawings | X | ||

Models | X | ||

Documents | X | ↔ | (X) |

Projects | X | → or ↔ | X |

Customers | X | ↔ | X |

Prices | X | → or ← | X |

Connections between objects | X | ||

Statuses | X | → or ↔ | X |

Connecting ERP to Flow

Connecting these two information systems is done through a separate development project.

An expert from Vertex Systems Oy, together with the customer company, defines and records the customer’s needs.

An expert from Vertex Systems Oy, together with the ERP provider, implements the necessary link between the ERP system and Flow.

Vertex Systems Oy has created dozens of links between Flow and various ERP systems.

Item and Structure Transfer

Activate transfer according to workflow

The system administrator can set the transfer of items and structures to activate according to Flow’s workflow.

For example, the status "Finished" or "Approved" activates the transfer of the item and product structure to the ERP system.

Start the transfer

The transfer is launched when the items reach the status required for the transfer.

The designer or checker changes the status of the finished product structure and its parts in Flow.

See: Change object status