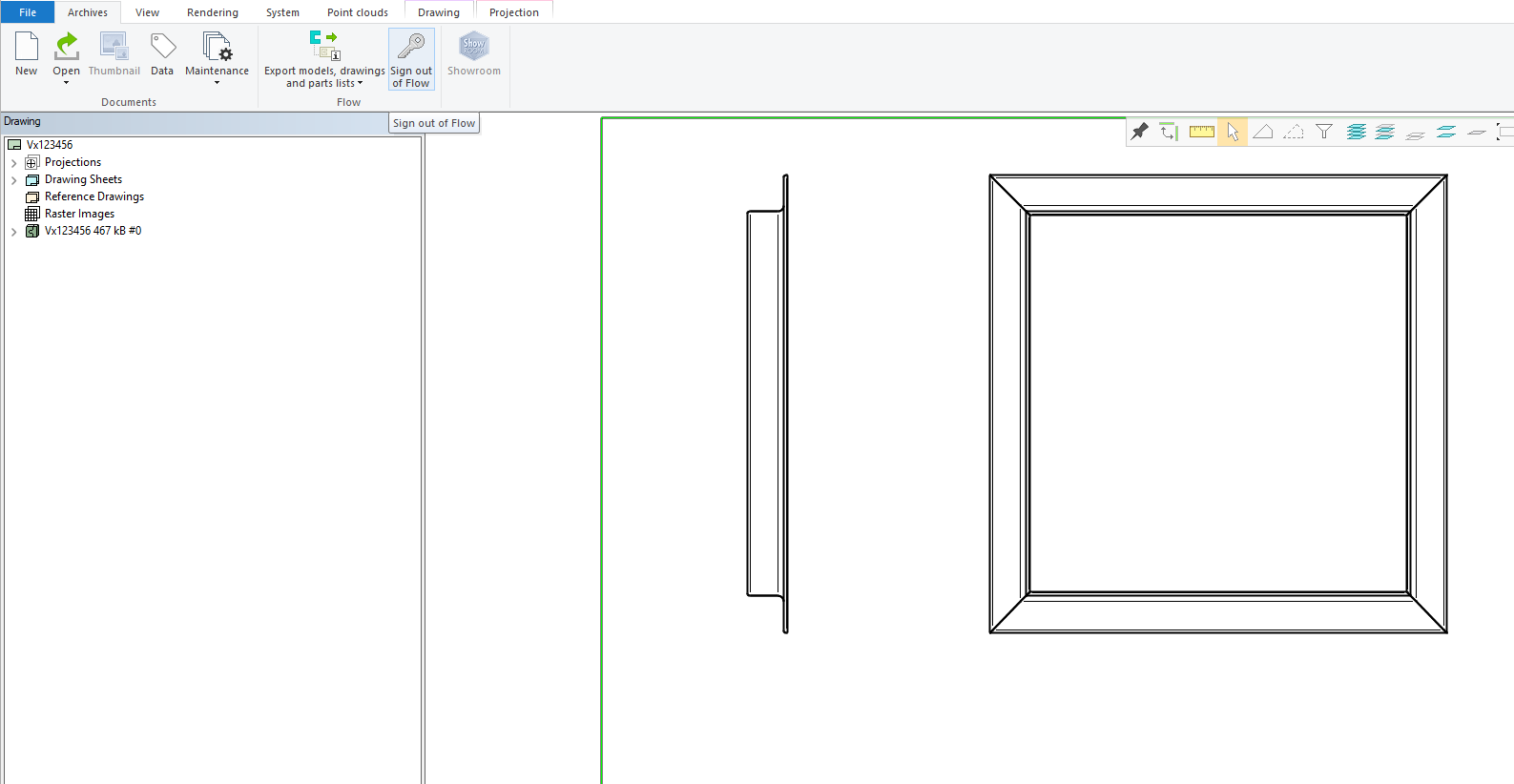

Assembly without items

Background

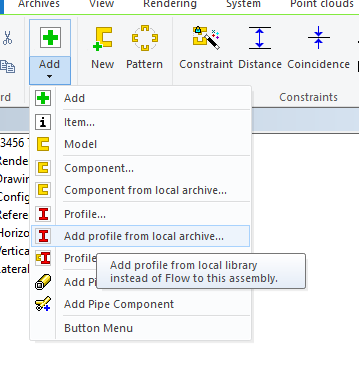

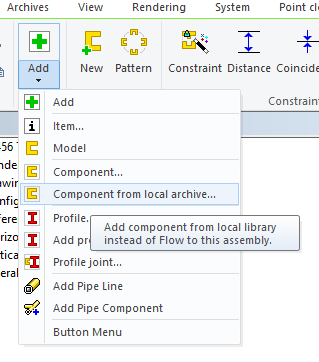

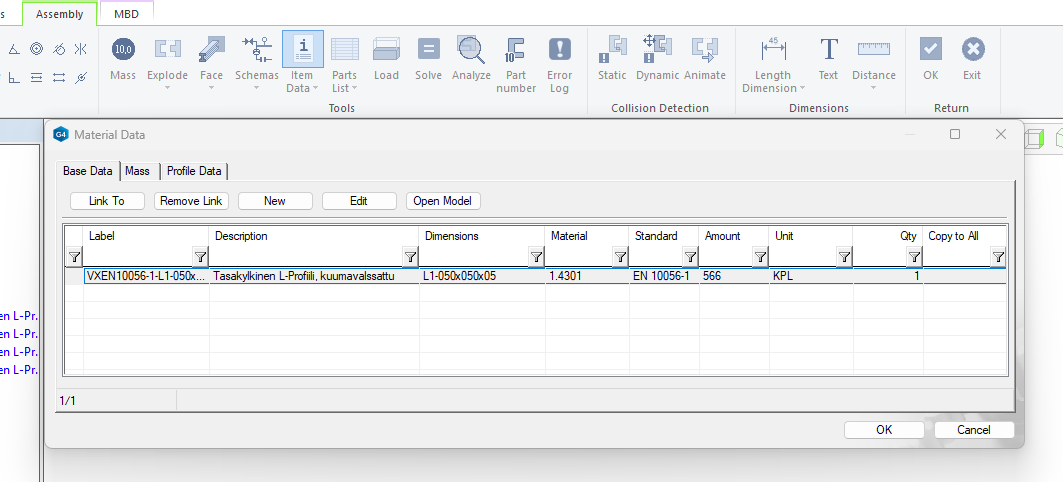

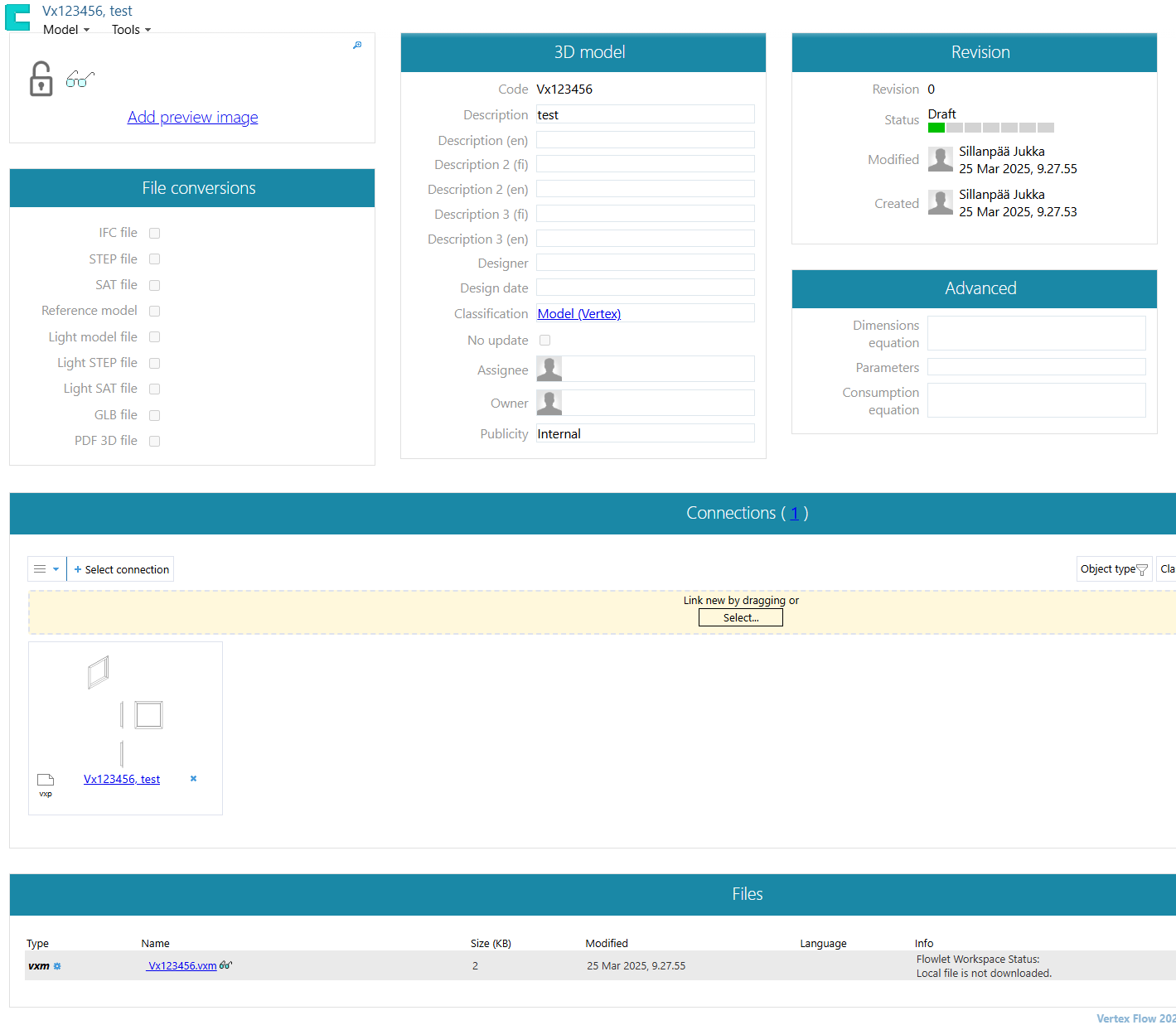

Need: The goal is to design an assembly where parts are purchased directly based on drawings, without relying on the formal production item system. Examples of this include fixtures, jigs, and other production aids needed for manufacturing, where the required materials are not listed in the ERP system.

Another common scenario is outsourcing the entire assembly, where the items for the parts are not in Flow and are not necessary, as the subcontractor will purchase or manufacture the parts. However, even in such cases, a bill of materials is often required to ensure the subcontractor uses the correct parts or materials.